A Guide to Understanding EV Batteries

This guide is intended to gather all the information about how EV (electric vehicle) batteries work and the components and mechanisms that enable your EV to function efficiently.

What is an electric vehicle battery?

An electric vehicle battery provides the electrical power to run your EV. At around 1,000 pounds, they are the heaviest part of your car and the costliest, although prices have decreased significantly in recent years.

What is an EV battery made of?

EV batteries are composed of a variety of metals and minerals, which are as follows:

- Anode – Graphite

- Cathode – Lithium, aluminum, nickel, manganese, iron, cobalt

- Separator – Polyolefin, a microporous polymer

- Electrolyte – Lithium hexafluorophosphate

- Current collectors – Aluminum (on the cathode side) and copper (on the anode side)

- Casing – Aluminum, steel

Most common types of EV batteries

No understanding of EV batteries is complete without looking at the common cell chemistries within EV battery cells.

Lithium-Ion

Lithium-ion batteries are the most common and most popular EV batteries today due to their cost-efficiency and excellent energy storage.

Nickel Manganese Cobalt

Nickel manganese cobalt batteries provide a more balanced delivery of power and good energy storage.

Nickel Metal Hydride

Nickel metal hydride batteries were commonly found in the earliest forms of hybrid cars, including the Prius. While they have largely been replaced by lithium-ion batteries, they can still be found in the 2020 Toyota Highlander and a few other hybrid vehicles.

Lithium Sulfur

While these batteries have large energy storage capacity, they need to heat up first before being able to generate enough power to run an EV. They are more commonly found in EV buses.

Lead Acid

Once the preferred battery type because they are low maintenance and easy to replace, lead acid batteries are now surpassed by lithium-ion ones and are now mostly seen in low-performance EVs like golf carts.

How do EV batteries work?

In this section, we will dive into each part of the EV battery and how it works as a whole.

Electric vehicle batteries have six major components: two electrodes, the anode (the negative electrode) and the cathode (the positive electrode); electrolyte; separator; current collectors; and casing/housing.

EV batteries have two main phases, namely the DISCHARGE and CHARGING phases. During the DISCHARGE phase of EV batteries, an electrochemical reaction occurs in which ions flow from the anode to the cathode through the electrolyte and separator, releasing electrical energy. Current collectors gather this energy and distribute them to external circuits in the electric vehicle’s various sub-systems.

Meanwhile, the reverse happens during the CHARGING phase. The flow of ions now moves from the cathode to the anode where electrical energy is stored in the electrode and the current collectors for use by the electric vehicle the following day.

As discussed in a previous article, future EV battery technology hopes to see a reduction in the charging time (normally over a period of hours overnight) of EV battery packs.

How long does an EV battery last?

Automotive industry estimates the current crop of EV battery cells have a projected lifespan of 15 to 20 years (100,000 to 200,000 miles). Note that despite the aging of EV batteries, owners may not detect reduced performance because the batteries have a large capacity to begin with and minor losses are not noticeable.

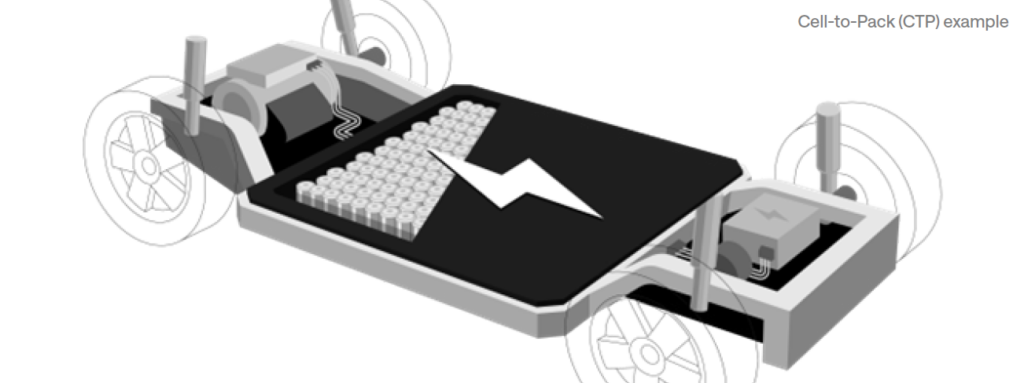

EV battery modules and pack designs

EV battery packs consist of modules, which, in turn, consist of individual battery cells. This allows optimal flexibility to configure various sizes of the battery packs.

EV battery cell, module and pack: key differences

EV batteries are composed of the following components, the differences of which will be listed below.

- EV battery cells – basic units of an EV battery that functions to store and deliver energy.

- EV battery modules – consists of EV battery cells connected in series or in parallel. Each unit produces a certain voltage and meets a specific energy capacity.

- EV battery packs – consists of EV battery modules connected in series or in parallel and enveloped in a robust casing. They also contain other components for cell monitoring and thermal management.

How are EV battery packs manufactured?

EV battery packs are manufactured according to an EV battery design.

The anode and cathode are first installed within the casing. They are wrapped in thin, metal foils known as current collectors. They are then isolated from each other by a separator to prevent short circuits. This assembly is then immersed within a liquid electrolyte prior to sealing in the casing. The cells are then subjected to moisture and leak checks which can cause corrosion, fires or explosions.

Next, the single cells are assembled into EV battery modules (normally there are 12 battery cells per module but they may vary across EV makes and models). The modules are then stacked together within a robust housing to protect it from physical shocks. Like the individual cells, the modules are also tested for moisture seepage and leaks.

Finally, the modules are assembled manually into EV battery packs within a rigid housing. The process not only involves stacking the modules, but also ensuring that electrical connections are done correctly, and fine-tuning is observed.

What are laminated busbars?

Laminated busbars are multi-layered and composite structures connected with a platoon. They are used as the electric current distribution system to the main parts of an EV.

These offer greater customization, quick installation, reduced overall system costs, and greater performance reliability in EV batteries.

Sustainability in EV battery design

Future EV battery technology is focused on finding easily obtainable or reusable materials from the environment.

One of the best sources of materials are old batteries. Some are brought to recycling plants where they are shredded and important metals such as lithium, aluminum, and copper are obtained from the electrodes. A sustainable EV battery also promises to do away with cobalt, which is toxic and can only be mined in the Congo.

There is much potential in the future for EV batteries that can hopefully make costs more affordable.