ADVANCED MOBILITY

Over recent decades, the use of solderless, Press-Fit technology has become ubiquitous in the automotive industry due to its major benefits in terms of streamlining production, eliminating secondary soldering processes, and reducing costs, while consistently providing robust, long-life interconnects between and within automotive electronics systems, including demanding on-engine applications.

More recently, the trend toward the usage of Organic Surface Preservative (OSP) finishes on automotive PCBs and other modules have raised the question of how Press-Fit technology can best be integrated for use with OSP.

This article provides an overview of the issues involved and offers new testing data regarding the efficacy of Press-Fit in conjunction with industry-standard OSP finishes.

Background on Press-Fit Usage in Automotive Applications

Press-Fit technology has been proven to provide significant benefits for a wide range of applications, especially in the automotive and power module industry segments.

Some key driving factors that have led to widespread adoption of Press-Fit include:

- Eliminating the risk of insufficient solder joints, cracking, flux contamination, and other solder formation problems

- Strong, solder-free, repeatable and highly reliable interfaces

- Verifiable assembly techniques with integrated force-monitoring

- Automated Press-Fit assembly processes for consistent results

- Ability to apply Press-Fit at room temperature avoids extra PCB thermal cycle

- Direct-contact interfaces with high normal force

- Excellent electrical and thermal transfer characteristics

- Ability to withstand CTE mismatch forces during thermal cycling

- High current carrying capacity for power-oriented applications

The excellent thermal profile of Press-Fit interconnects is an especially important factor for long-term life-cycle reliability, particularly within a wide temperature range and harsh environmental conditions, such as automotive electronics and many power-module designs. For example, on a cold winter day, going from engine start-up to standard running temperatures could potentially require an under-hood engine-mounted electrical sub-system to go from 0º C to 150º C in less than ten minutes.

The combination of high-current capacity, high reliability and a wide range of configuration alternatives have made Press-Fit a predominant interconnect design choice for automotive and power-oriented applications. Elimination of solder-related hassles while at the same time improving reliability, performance and reducing production costs offers manufacturers compelling reasons for using Press-Fit technology.

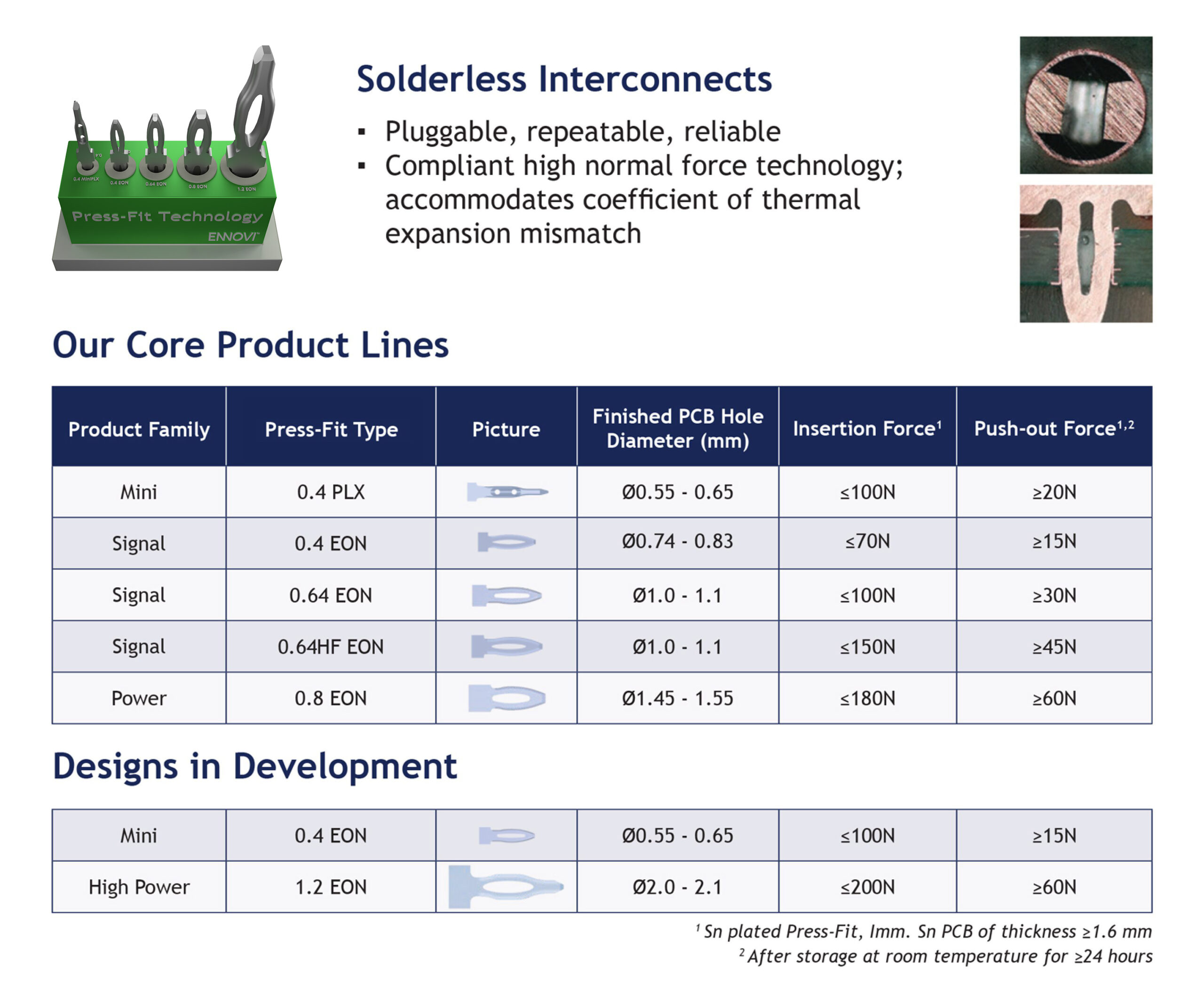

Fig 1. Specifications for ENNOVI’s Press-Fit Core Product Lines & Designs in Development

Overview of OSP in Automotive Electronics

Many automotive industry manufacturers, particularly in Asia, have been moving toward the use of Organic Surface Preservative (sometimes also called Organic Solderability Preservative) to protect against oxidation on PCB boards.

OSP uses water-based organic compounds that selectively bond to copper and thereby protect the PCB copper until soldering. Compounds typically used for OSP are from the azole family such as benzotriazoles, imidazoles, and benzimidazoles. These adsorb on copper surfaces, by forming coordination bonds with copper atoms and form thicker films through the formation of copper (I) – N–heterocycle complexes. The typical film thickness used for OSP is in the tens to hundreds of nanometers.

The trend toward OSP has been accelerating in recent years as more manufacturers see it as a cost-saving alternative to conventional immersion tin (ImmSn) plating. In addition, OSP eliminates the issues with “tin whiskers” that can form during soldering processes on immersion tin PCBs.

The OSP coating’s temporary oxidation protection breaks down by temperature load, condensation water, acids (fluxes), or organic solvents (fluxes). This makes OSP seamlessly compatible with most standard soldering processes.

Keys to Success for Combining Press-Fit and OSP

As OSP becomes more prevalent in automotive manufacturing, it is important to make sure that OSP processes are also compatible with proven and widely deployed Press-Fit technology.

It is important to make sure that the use of Press-Fit interconnects in OSP coated PCBs does not degrade the mechanical performance (insertion force, retention force, etc.), the electrical performance (connectivity, current carrying capacity, etc.) or environmental performance (vibration, thermal shock, corrosion, etc.)

What the Testing and Evaluation Data Tells Us

Fig 2. ENNOVI’s MiniPLX Pins

As the global leader in pioneering, developing, and enhancing Press-Fit technology, ENNOVI has taken the leadership step of proactively testing Press-Fit interconnects across the full range of key parameters.

The following data is from qualification testing of ENNOVI Press-Fit MiniPLX pins, which are compact 0.4mm pins developed specifically to meet automotive industry standards. Testing was conducted by ENNOVI’s ISO/IEC accredited test labs, of which there are three regionally located labs to serve the global needs of our customers.

The MiniPLX pins tested had the following characteristics:

- Material: CuNiSi

- Plating Type: IndiCoat™

The PCBs used for conducting the tests had the following construction characteristics:

- Material: FR-4, 1.6 mm thick

- Plating Types: OSP

- Final Plated-Through Hole (PTH) sizes: Ø0.55 mm for a lower limit hole, Ø0.65 mm for an upper limit hole

- Copper wall thickness: 0.025-0.075 mm

The test samples were subjected to various performance tests outlined in IEC 60352-5, SAE/USCAR-2, EIA 364 and IEC 512 A. The following tests were performed:

- Mechanical Tests

- Push-In Force

- Push-Out Force (test after 24h)

- Contact Resistance (test after 24h)

- Environmental tests following IEC and IPC standards

- Vibration

- Thermal Shock

- Climatic Sequence

- Dry Heat

- Mixed Gas Corrosion

Test results were as follows:

- Forces: The maximum push-in force value measured was 52.6 N and occurred at a lower limit hole size condition. The minimum push-out force value was 30.9 N at the upper limit hole size after environment conditioning. The minimum push-out force value before environmental testing was 36.5 N.

- Resistance: All samples successfully passed all environmental tests as shown. The maximum interface resistance measured was 0.129 mΩ after environmental conditioning. This value is well below the design requirement of less than 0.5 mΩ maximum.

- PTH Integrity: Plated-through hole deformation values for both transverse and longitudinal sections are within design requirements. In the transverse direction, the maximum drill hole contour deformation measured was 15.1 μm and the minimum remaining plating thickness measured was 25.0 μm. In the longitudinal direction, the maximum vertical trace deformation was 24.3 μm.

- Test Item Acceptance Criteria Testing For:Result vibration increase of contact resistance < 0.5 mΩ movement of contact points, fatigue pass thermal shock movement of contact points, fatigue pass climatic sequence stress relaxation of terminal and PCB growth of oxide film pass dry heat mixed gas corrosion effectiveness of barrier plating pass.

Summary

As automotive manufacturers continue moving toward OSP coatings to achieve the associated cost savings and reduction in tin whiskers, they need to be assured that OSP processes are compatible with their widespread usage of Press-Fit technology.

Therefore, it is important to work with Press-Fit experts who are proactively committed to empirical testing and confirmation that Press-Fit designs maintain all critical performance parameters in OSP coated PCBs.

ENNOVI has already taken a series of steps to test and certify all our Press-Fit interconnects for OSP compatibility.

In addition to the specific results cited for MiniPLX, additional testing that applied the same rigorous processes have confirmed that the entire family of ENNOVI Press-Fit offerings also work flawlessly in OSP settings.

In particular, the combination of OSP PCB surface coating and ENNOVI’s IndiCoat™ plating avoids 100% of Sn whiskers because there is no Sn in the interface at all.

At ENNOVI, our global organization and regional testing labs make it simple for manufacturers anywhere in the world to get local support for any questions or special requirements to support the integration of Press-Fit with OSP.